Globalization is changing the way in which we produce, distribute and consume food. Along with the growing global population and the rising middle class in many countries comes the need for transporting food to densely populated areas over longer distances.

Indeed, food security is becoming an increasingly important issue in global supply networks. If not transported within specific temperature ranges, it may become unsaleable, or shelf life can decrease significantly. Therefore, it's critical to monitor and record temperatures from the early stages of processing until the delivery of finished goods to consumers. This is not an easy task and involves setting up a temperature-controlled food supply chain (i.e. a food cold chain) that integrates stringent and efficient operational controls to ensure that food reaches the final consumer safely.

Food Cold Chain Management

Food cold chain management lies at the center of the food distribution system. Sending food across borders, continents and around the world is a complex journey. It involves refrigerated docks, numerous refrigeration zones within distribution centers, refrigerated vehicles, and special thermal packaging solutions.

The challenge is to make sure that food remains under controlled temperature conditions throughout the distribution process. A temperature excursion can render food micro-biologically unsafe, or reduce the product’s life. As is typical with biological processes, degradation processes occur faster when exposed to elevated temperatures. As a general rule, degradation processes typically double their rate for each increase of 10⁰C, often referred to as the Q10 quotient.

Take for instance the impact of temperature on the storage of fresh green vegetables. At an optimal cold storage temperature of 0⁰C, fresh green vegetables can last up to 1 month. However, if storage temperatures increase to 10⁰C, the storage potential decreases to 2 weeks. This demonstrates the importance of properly managing the cold chain for food and other thermosensitive products. Lack of effective cold chain measures can reduce the product’s shelf life and thus lead to considerable costs and losses.

Causes of Food Loss

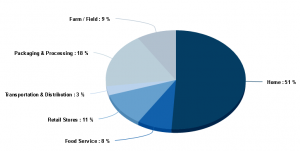

On a global scale, a third of all produced food is wasted. From a Canadian standpoint, 30 to 40% of food is lost along the value chain, representing approximately $27 billion each year. The graph below illustrates the proportion of food estimated to be lost along the food value chain in Canada:

Some causes of food loss at the transportation and distribution stage include improper cold chain packaging, inappropriate storage conditions, or lack of communication between supply chain partners. According to VCM International, reducing food waste can help businesses diminish operating costs by 15 to 20% and increase profitability by 5 to 11%.

The True Cost of Food Loss

Waste costs accumulate along the food value chain. When a pallet of food becomes unsaleable and spoiled due to an uncontrolled temperature excursion, the most visible direct cost of that loss is typically the invoiced price of food. However, there are many hidden costs to take into consideration as well. For example, consider the capital investments in infrastructure and inventory, along with the labor, energy, disposal fees, price markdowns, transportation, audits, and depreciation of machinery. Thus these factors only represent some of the indirect costs associated with food loss, which can take a hefty toll on a company’s bottom line.

Consequently, mastering the cold chain is a key aspect of running a profitable business. Smart cold chain management offers significant benefits to those who effectively implement it: enhanced product quality, compliance and security and overall improved efficiency.

Want to master your cold chain? Download our 4-Step Approach to Cold Chain here!

References

Kitinoja, L. (2013). Use of cold chains for reducing food losses in developing countries. The Postharvest Education Foundation. Retrieved from: http://www.postharvest.org/Use%20of%20cold%20chains%20PEF%20white%20paper%2013-03%20final.pdf

Sherman, D. (2014). A wasted opportunity: Addressing $31 billion in food waste in Canada. Canadian Grocer. Retrieved from: http://www.canadiangrocer.com/top-stories/a-wasted-opportunity-addressing-31-billion-in-food-waste-in-canada-47068

Uzea, N., Gooch, M., & Sparling, D. (2014). Developing an Industry Led Approach to Addressing Food Waste in Canada. Provision Coalition. Retrieved from: https://www.provisioncoalition.com/Assets/website/PDFs/Provision-Addressing-Food-Waste-In-Canada-EN.pdf

Uzea, N., Gooch, M., & Sparling, D. (2014). $27 Billion Revisited: The Cost of Canada’s Annual Food Waste. Value Chain Management International Inc. Retrieved from: http://vcm-international.com/new-report-annual-food-waste-in-canada-is-31-billion/

Winkworth-Smith, C.G., Foster, T.J., & Morgan, W. (2014). The Impact of Reducing Food Loss in the Global Cold Chain. The University of Nottingham. Retrieved from: http://naturalleader.com/wp-content/uploads/2016/04/UTC-Nottingham-Report_3-30_FINAL.pdf